IBB16 ®

The leading system for trenchless pressure pipe rehabilitation

Less environmental pollution

Less process costs

for disposal of soil, old pipe and transport

Faster implementation

Less traffic obstruction

due to smaller excavation pit

Environmental Aspects

Potable water pipe DN 800, 150 m length

Soil volume to replace

IBB16 72m 3 / Dig and replace 2.700m 3

Old pipe disposal

IBB16 0,29m 3 / Dig and replace 7,35m 3

Truck loads

Trenchless 3 / Dig and replace 98

Construction time

Trenchless 10 days / Dig and replace 60 days

Replacement of Pavement

IBB16 12m 3 / Dig and replace 225m 3

Reduction of the emissions of all greenhouse gases caused by construction machinery such as CO2, CO, NOx, TOC, and SOx, smoke and other particulates.

Very significant for every meter converted from trench to trenchless methods!

Solvent free

No volatile organic substances

Hydrolisis resistent

Long-term material performance over 50 years

Styrene free

resin available

No Emission

of environmentally harmful components

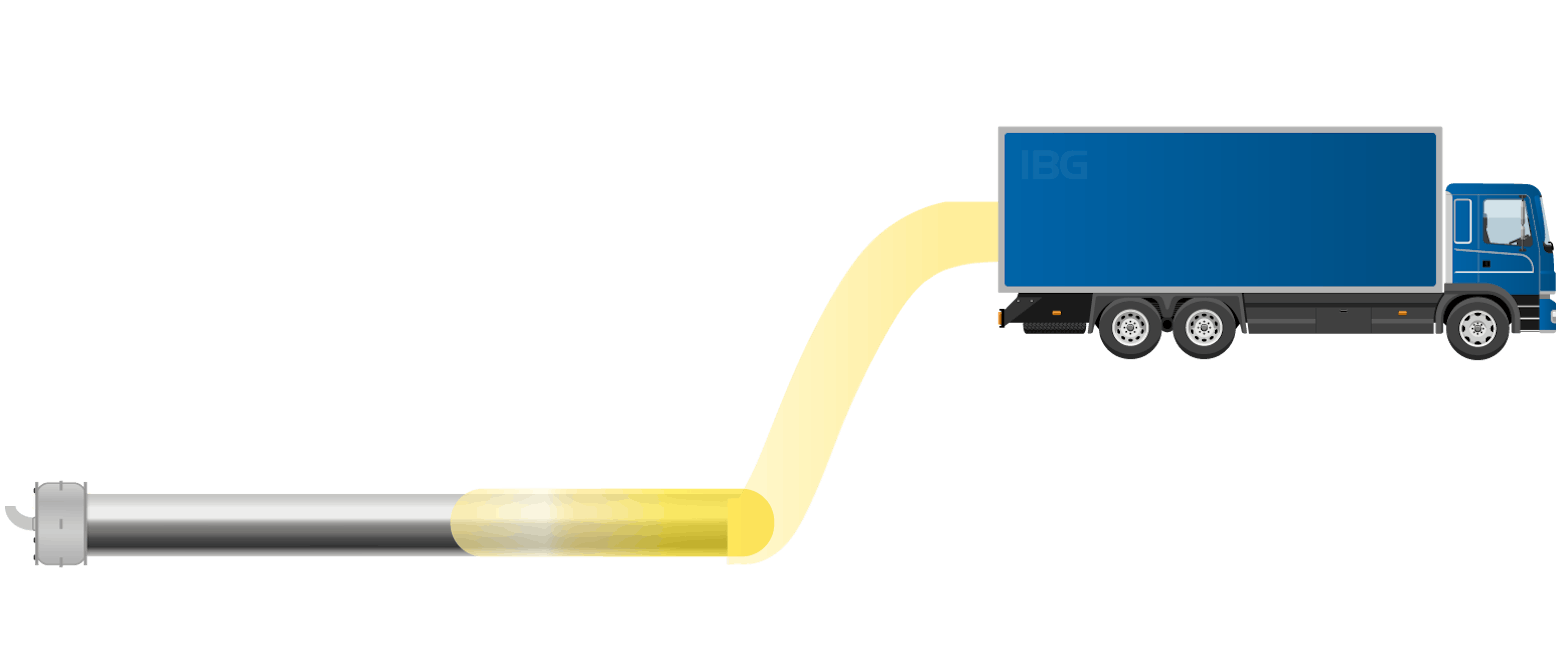

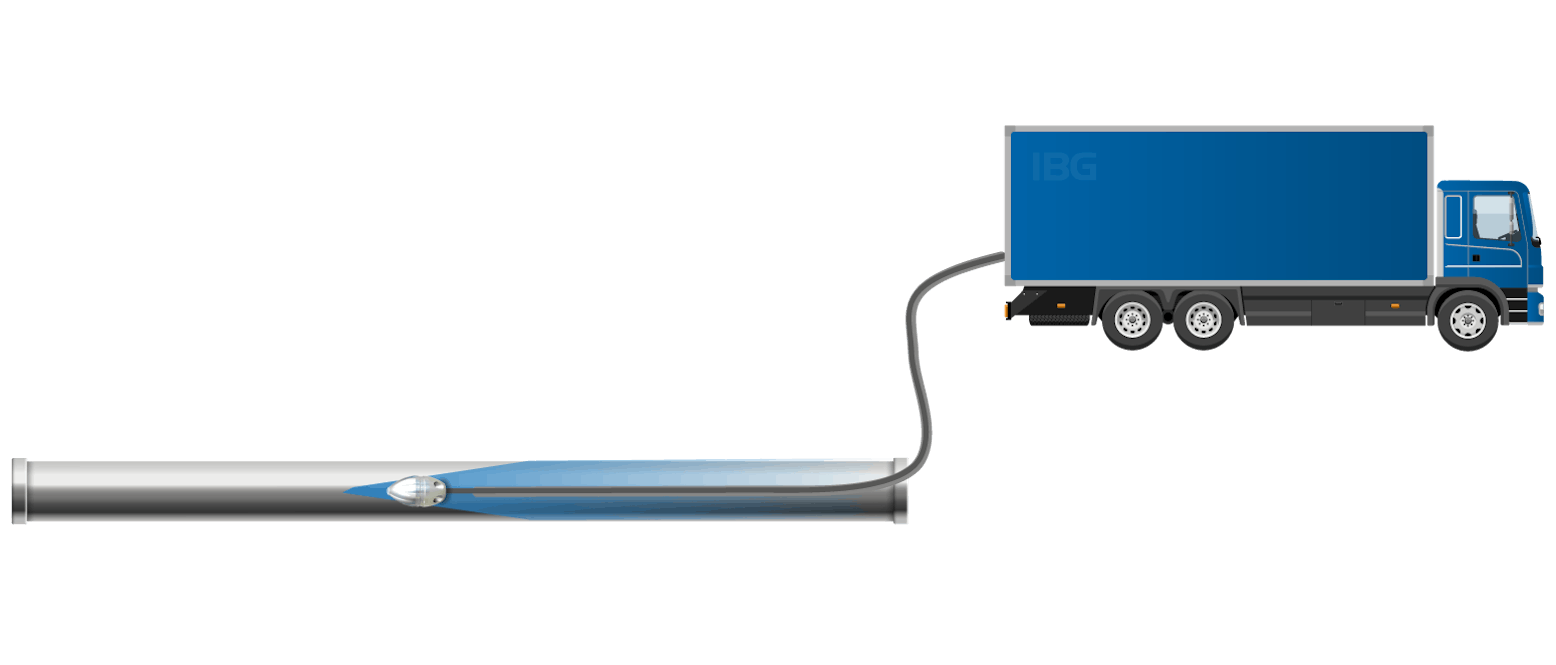

Process presentation IBB16 ®

About IBB16 ®

The IBB16® system is a hybrid hose pipe relining (without bonding with the old pipe) applicable for the rehabilitation of pressure pipes.

The system combines two pipe liners with different properties to achieve the required criteria for the rehabilitation of a pressurized water pipe.

The system combines the IBG UV + Steam systems to the system IBB16®.

Where to use IBB16 ®

The system can be used in pressure pipes up to an operating pressure of 232 psi (16 bar).

The minimum pipe diameter is: DN 150

The maximum pipe diameter is: DN 2000

System description IBB16 ®

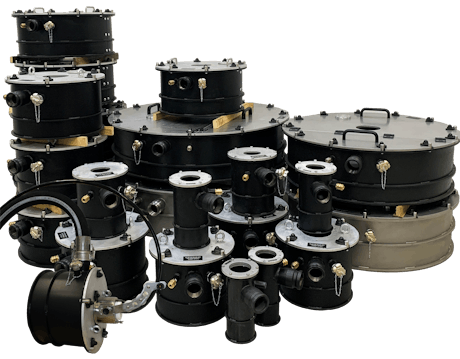

The impregnation of the liner is performed at the liner factory. The installation of the liner takes place in one or more rehabilitation conduits defined by two or more pits or line openings.

The liner is pulled into the line using a pulley, typically with winch support and sliding protective foil, pulled onto packers and expanded using air pressure.

Curing is performed by exposure from a UV light source. The entire curing process is controlled and documented using installed sensors.

The finished product is a statically fully structural, seamless, flexible plastic pipe.

2. Inspection

Pipe inspection by robot inspection - Search for root ingrowths or similar

4. Second cleaning

Second high-pressure cleaning of the pipe to be rehabilitated

5. Installation

Installation of the UV liner including curing

6. Inversion

Installation of the 2nd layer INVERSION - Steam curing Epoxy + PE coating

7. Final Pressure Test

Final inspection and pressure test

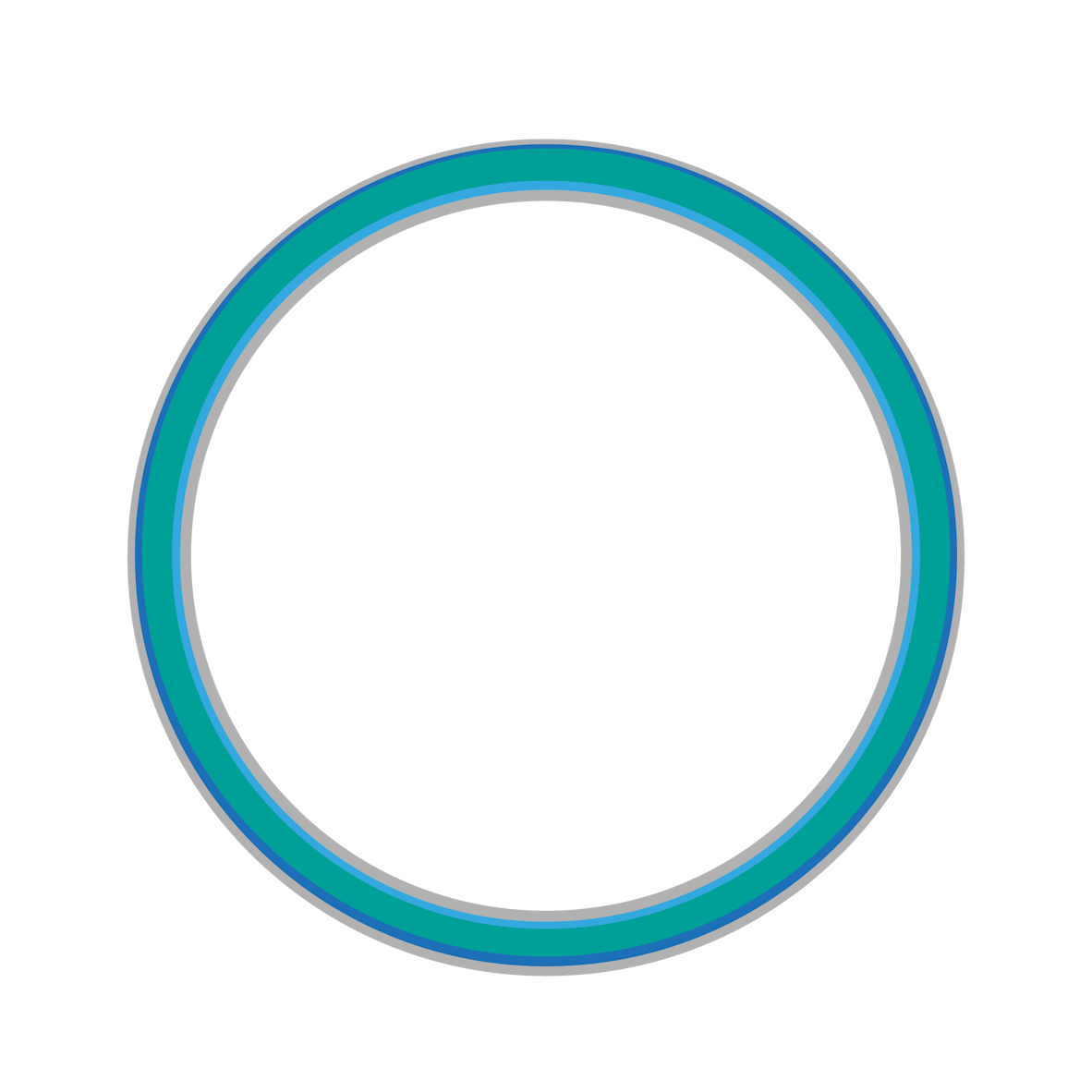

Glass-Polyester resin Laminate - UV System

Epoxy resin layer - Steam curing

PE Inner-coating with felt layer

Seismografic Aspect

IBB16 CIPP system tested for seismic conditions as per recognized standard

“Teicordia GR-63-CORE Zone 1, 2, 3 & 4“.

Safety factor achieved 16.2 times of the required loading –

Testing done by accredited SGS laboratory in South Korea.

Florence, Italy

Diameter: DN 800

Working pressure: 6 bar

Shanghai, China

Diameter: DN 800

Pressure: 10 bar

References

Naples, Italy | Freiburg, Germany | Venice, Italy | Bergen, Norway | Shanghai, China | Moscow, Russia | Kiev, Ukraine | Lodz, Poland | Lviv, Ukraine | Florence, Italy | Shengdou, China | Oslo, Norway | Calabria, Italy | Prague, Czech Republic ...

Operating Pressure

16 bar 232 psi

Working Distance

500 m + 1.600 LF +

Diameter

150 mm- 2200 mm 6" - 86"

Capable of multiple Bends

Up to 45°

NSF

Société Générale de Surveillance

Siebert + Knipschild Engineering Office for Plastics

Institute for Underground Infrastructure

"Despite having the thinnest wall thickness compared to its competitors, IBB16 ® does not have any limitations on working pressure"

(16 bar, with the option for higher pressure upon request)

Venice, Italy

Diameter: DN 1200

Working pressure: 6 bar

Freiburg, Germany

Diameter: DN 600

Working pressure: 8 bar

Naples, Italy

Diameter: DN 1365

Working pressure: 16 bar

Bergen, Norway

Diameter: DN 300

Working pressure: 10 bar